3D Printers and Their Various Applications

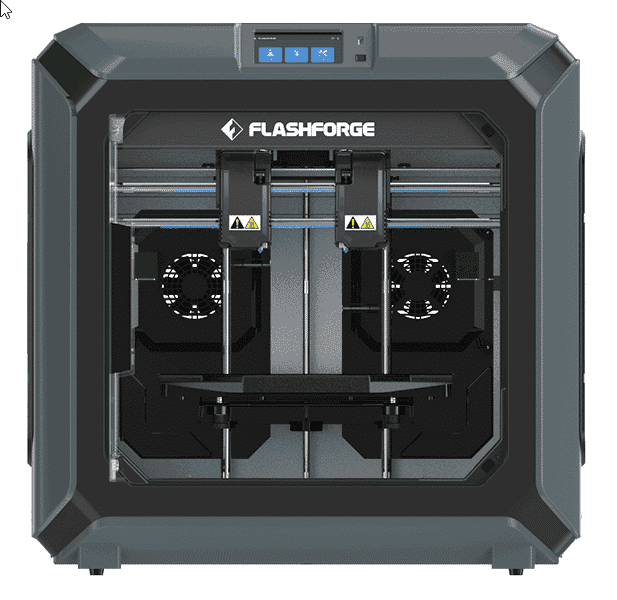

We’ve reached a technological age where the devices and various other technological advances showed in sci-fi films, as well as TV shows a couple of decades ago are now a reality, minus the teleportation and time travel. Apart from that, we have actually progressed into creating a device that will produce anything. This gadget is called a 3D printer.

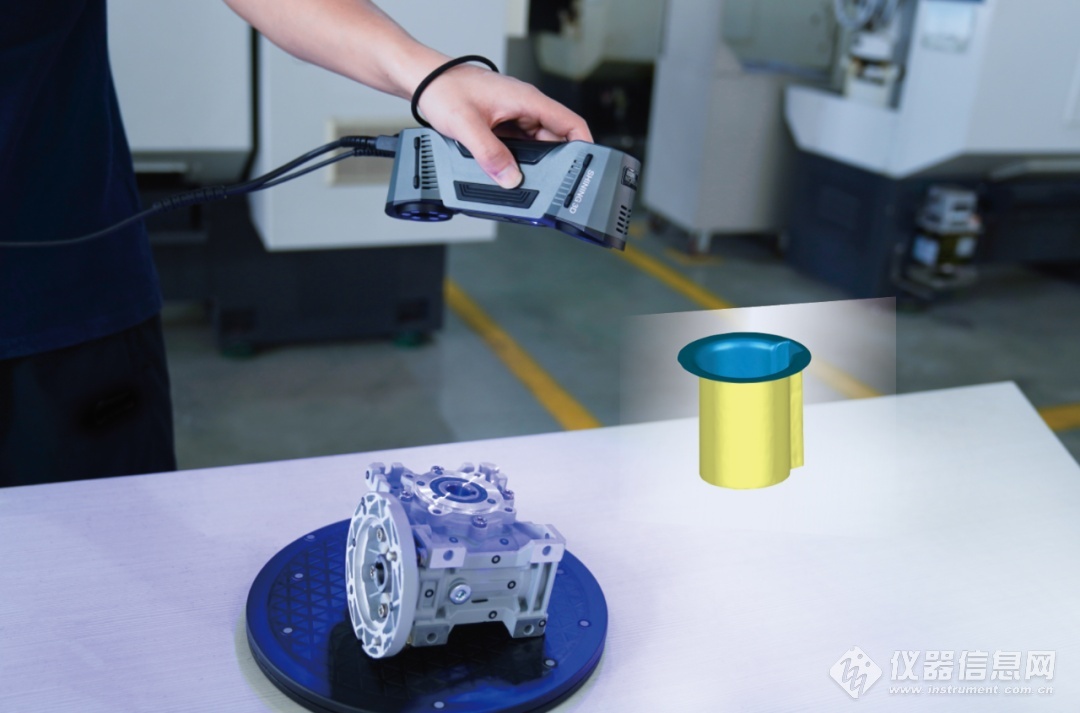

It is essentially a printer, but it prints 3-dimensional physical items out of digital data from CAD programs. Anything imported into a CAD program will be changed into a collection of guidelines that are understood by the printer. The render or image is then sliced up into thousands of horizontal layers, and published layer by layer. Think about it as a digital cake, but with many thousands of layers.

The printer repeats steps over and over again. Next, the printer uses a fraction to lower the model, and the roller of the printer spreads out a new layer. Then, the laser solidifies some specific areas of that layer, which will essentially become parts of the 3d print. This procedure is repeated until the creation of the model is finished.

3D printing allows you to print anything, from a cellphone casing to shoes to headwear to prosthetics to scale models. But does it have any real-world application or contribution to any industry?

Believe it or not, the prosthetic, as well as the medical equipment industry, have currently welcomed the concept of 3D printing with open arms. Specialists in Belgium were able to give an 83 year old woman a jaw implant, which was a titanium-plated 3D printed jaw. Surgeons have the ability to work a 3D printer along with a CAT scan to duplicate the size and shape of tumours. Soon, medical professionals will certainly have the ability to create prosthetic limbs straight out of a 3D printer.

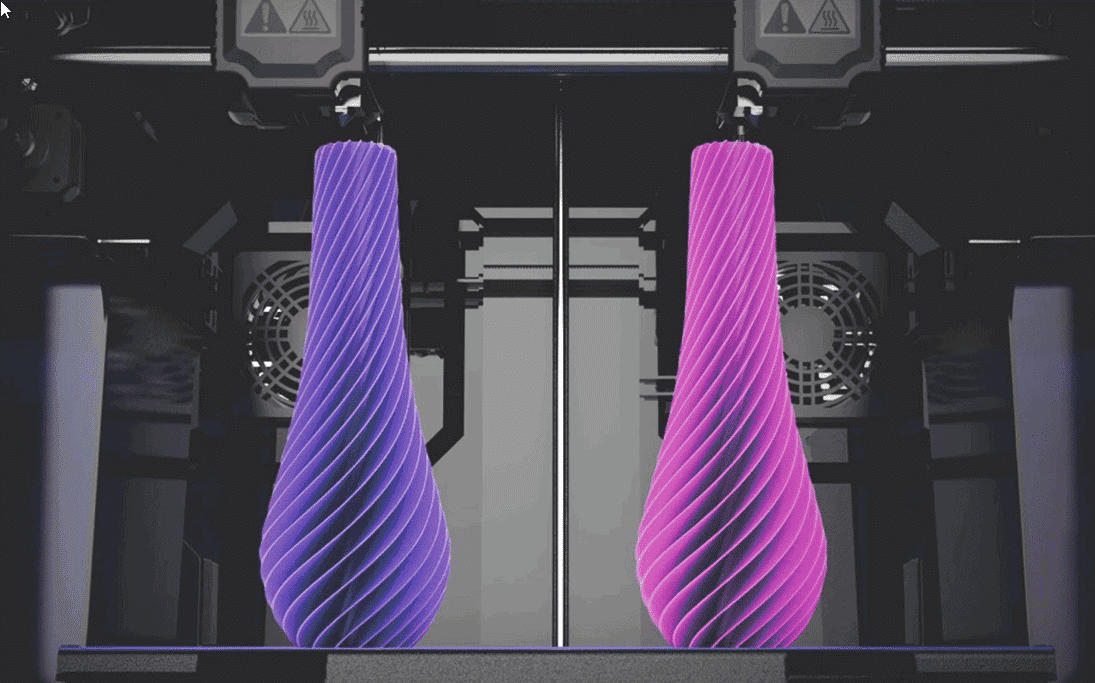

3D printers can also aid in creating 3D models, or rapid versions. These models can vary from cars to space rocket to organs. This would make the task of R&D divisions a great deal simpler due to the fact that they already have a physical representation of the item they are servicing.

3D printers give new significance to the words “personalised gift”. Gone are the days where you print out an image of a friend or significant other and put them in a photo frame. With a 3D printer, you can in fact develop a doll or figurine version of that unique individual. 3D printers are additionally able to print out existing figurines and sculptures also.

3D printers also have the ability of printing out vehicle parts. In 2017, Andy Green was set to break the world record for land speed and he attempted it in a motor vehicle that was fitted with 3D printed compounds and a unique 3D printed steering wheel.