Video Guides

01 – Stripping Down The Printer

https://youtu.be/U5TEz2cgS5M

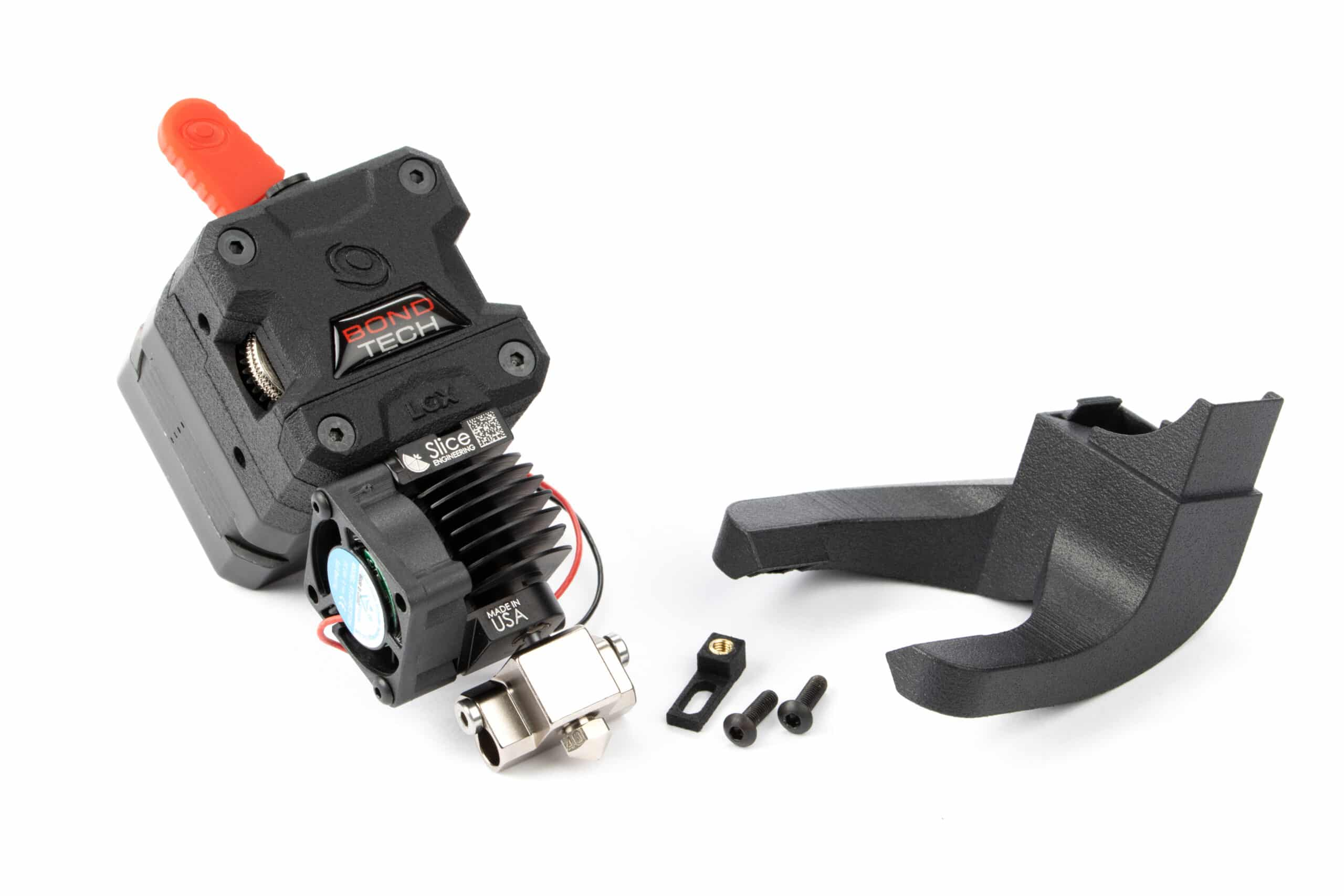

02 – Preparing the Copperhead hotend

https://youtu.be/fGVFmKP2wCk

03 – Preparing the LGX for Copperhead

https://youtu.be/2BCxD_s9-Mw

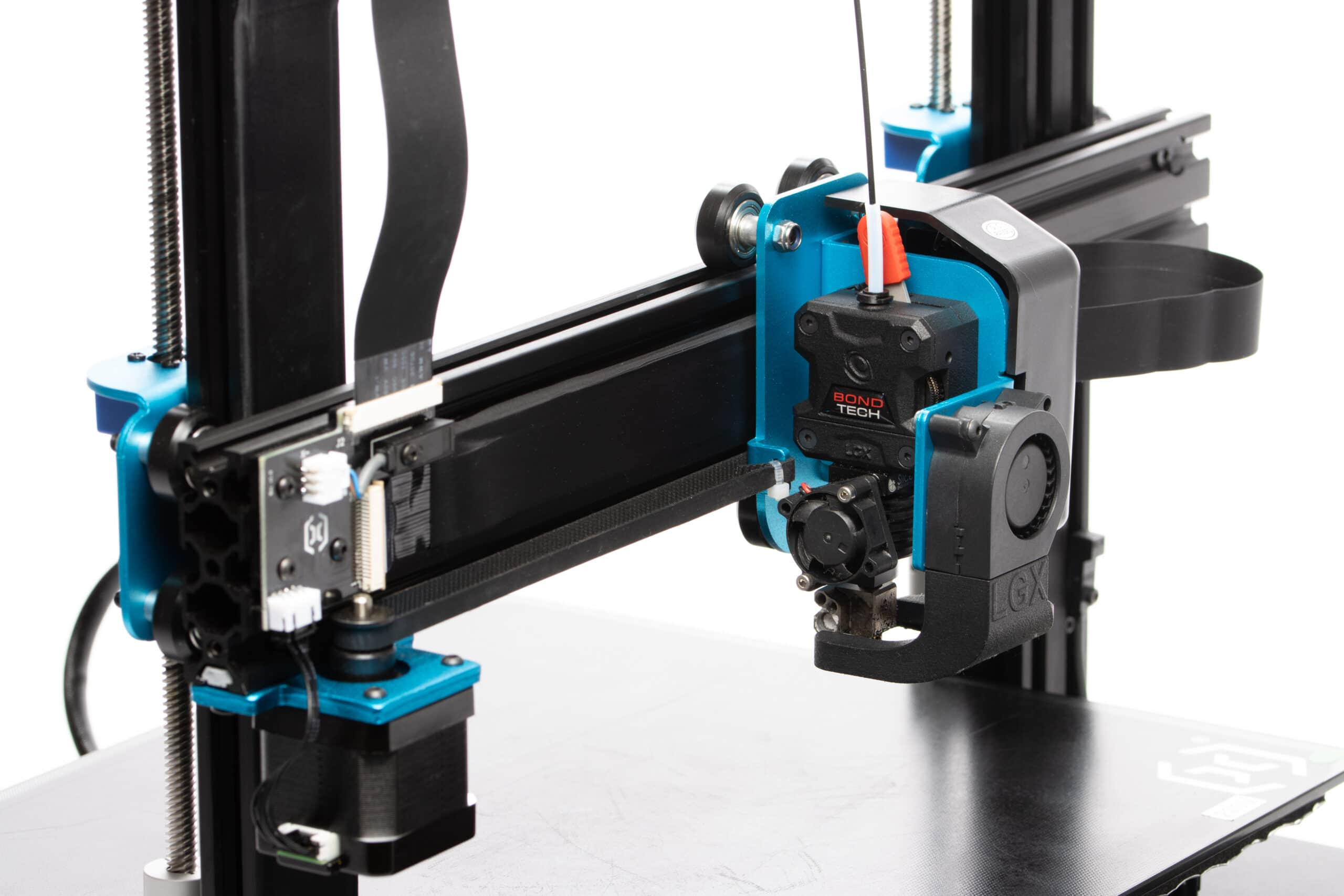

04 – Re-assembling the print heat

https://youtu.be/YG83-Pwgr8I

05 – Finishing Installation

https://youtu.be/kWkOi4_xpn4

LGX™ Webinar

https://youtu.be/-5v9_o3bHmg