MakerBot ABS Special Features

Acrylonitrile Butadiene Styrene (ABS) is one of the most common plastics used in injection-molding, found in many common products such as LEGOS, computer keys, power-tool housings, and automotive parts.

MakerBot real ABS is a real, production-grade ABS material formulation for creating strong and durable functional prototypes, manufacturing tools, and end-use parts. Unlike desktop ABS material formulations containing damaging modifiers and stabilizers that lead to warping and cracking, this real ABS formulation empowers engineers to achieve part properties close to injection molded parts with high dimensional accuracy, durability, and repeatability. Outpace your competition with better materials and better parts.

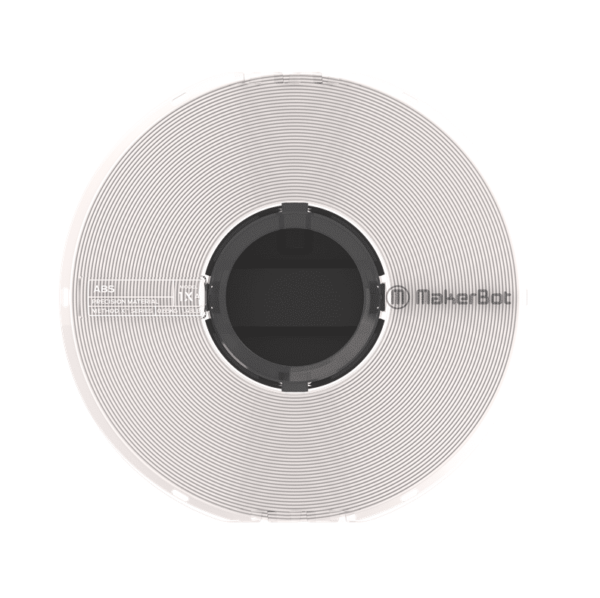

The ABS Material for METHOD X has been designed and tested to work perfectly with MakerBot’s industrial grade printer, and is shipped in a vacuum-sealed metalised polyester bag to preserve its quality right up until opening. The filament comes wound around a Smart Spool™ that contains all the information that the printer needs, including material type, colour, and remaining amount via an embedded RFID chip that communicates directly to MakerBot Print.

End-Use Parts: Custom parts, low volume production, and components that require high geometric complexity;

Liquid Containers

Signage & Graphic Displays

Enclosures for Electrical Equipment

Manufacturing Tools: Create tools, jigs, and fixtures at lower cost, with faster turnaround, and without the need for expensive skilled labour;

Manufacturing Tools and Aids

Robotic End Effectors

Product Testing Tools

Functional Prototypes: Get true fit and feel, test in real-world and beyond real-world scenarios, and expedite time to market in the same material as the final injection-molded part;

Consumer Product Prototypes

Appliance Assemblies

Automotive Parts

MakerBot ABS Specifications

Printer Compatibility: MakerBot METHOD X

Extruder Compatibility: Material Extruder 1XA, Support Extruder 2XA

Material Type: ABS

Spool Type: Smart Spool™

Software Compatibility: MakerBot Print

Support Material: Stratasys® SR-30

Dimensional Accuracy: Finished Part Dimensional Accuracy of ±0.2mm

Heat Deflection @ 66psi (ASTM 648): 84°C

Flexural Strength (Method 1, 0.05"/min): 65MPa

Flexural Modulus (Method 1, 0.05"/min): 77MPa

Tensile Strength at Yield (Type 1, 0.125", 0.2"/min): 43MPa

Tensile Modulus (ISO 527): 2,400MPa

Strain at Yield - Elongation: 2.6%

Notched Impact Strength (ASTM D256): 26J/m

Unnotched Imact Strength (ASTM D256): 1650J/m

Dimensions & Weight:

Spool Diameter: 218mm

Spool Width: 42mm

Material Diameter: 1.75mm

Net Weight: 650g

Operating Environment: Store ABS in the included vacuum-sealed metalised polyester bag to avoid moisture absorption from air and long-term exposure to humidity, which can compromise material quality and performance. Make sure the built-in desiccant is in the spool to absorb any moisture exposure during the material loading process.

Further Information

MakerBot METHOD bridges the gap between industrial and desktop 3D printing. It was developed from the ground up leveraging industry-leading Stratasys® patents including a heated build chamber, precision dissolvable supports, and dry-sealed material bays.

Engineers and designers use METHOD to create prototypes, jigs and fixtures, and end-use parts.

Learn more at https://www.makerbot.com/3d-printers/method/

There are no reviews yet.