MakerBot Nylon for METHOD

High Abrasion Resistance for Industrial Applications

Nylon’s ability to withstand high temperatures and its durability combine to give it above average abrasion resistance. Thus it is an excellent material for replacement parts in a manufacturing facility or distribution center.

MakerBot Nylon Special Features

MakerBot Specialty Nylon is an engineering-grade material that is optimised for high abrasion resistance due to its excellent flexural, tensile, and impact strength, not to mention a heat resistance of up to 180°C.

MakerBot Nylon is compatible with MakerBot's water soluble PVA for unrestricted geometric freedom and is ideal for demanding applications in the automotive and industrial products industries for both functional prototypes and end use parts.

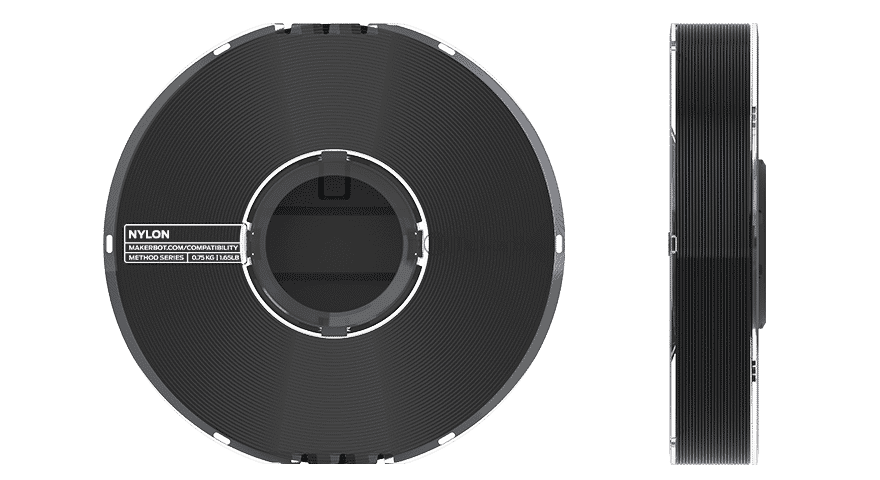

The Specialty Nylon for METHOD has been designed and tested to work perfectly with MakerBot’s industrial grade printer, and is shipped in a vacuum-sealed metalised polyester bag to preserve its quality right up until opening. The filament comes wound around a Smart Spool™ that contains all the information that the printer needs, including material type, colour, and remaining amount via an embedded RFID chip that communicates directly to MakerBot Print.

- Functional Prototypes: Nylon is a popular material that can be mass produced for industrial applications. In anticipation of large-scale manufacturing, it can be beneficial to prototype using the same material in order to more closely mimic the final product in form, fit, and function, but also in testing;

- Industrial Products

- Seat Belt Buckles

- Gaskets

- Manifolds

- End-Use Parts: In a shop or on a factory floor, nylon parts are used for augmented or original tools, jigs and fixtures, and replacement parts such as gears. Nylon's ruggedness makes it an ideal material for these end use applications;

- Gears

- Pulleys

- Nuts and Bolts

- Assembly Fixtures

MakerBot Nylon Specifications

- Printer Compatibility: MakerBot METHOD & METHOD X

- Extruder Compatibility: Material Extruder 1, Support Extruder 2

- Material Type: Nylon

- Spool Type: Smart Spool™

- Software Compatibility: MakerBot Print

- Support Material: MakerBot PVA

- Heat Deflection (ASTM 648, 66psi): 91°C

- Flexural Strength (ASTM D790, 15mm/min): 97MPa

- Flexural Modulus (ASTM D790, 15mm/min): 1,700MPa

- Tensile Strength at Yield (ASTM D638, 50mm/min): 66MPa

- Tensile Modulus (ASTM D638, 50mm/min): 2,200MPa

- Strain at Yield - Elongation: >10%

- Notched Impact Strength (ASTM D256): 187J/m

- Dimensions & Weight:

- Spool Diameter: 218mm

- Spool Width: 42mm

- Material Diameter: 1.75mm

- Net Weight: 750g

- Operating Environment: Store Nylon in the included vacuum-sealed metalised polyester bag to avoid moisture absorption from air and long-term exposure to humidity, which can compromise material quality and performance. Make sure the built-in desiccant is in the spool to absorb any moisture exposure during the material loading process.

Further Information

MakerBot METHOD bridges the gap between industrial and desktop 3D printing. It was developed from the ground up leveraging industry-leading Stratasys® patents including a heated build chamber, precision dissolvable supports, and dry-sealed material bays.

Engineers and designers use METHOD to create prototypes, jigs and fixtures, and end-use parts.

Learn more at https://www.makerbot.com/3d-printers/method/

There are no reviews yet.