Unboxing the Creality 200B (CR200B)

Today we are looking at the CR200B, a fully enclosed printer from Creality’s ever expanding range.

This sleek new machine, while not directly aimed at the professional market, promises high performance in many areas. With an upgraded nozzle and hotend assembly, large responsive touch screen with new UI, carborundum glass bed with easy removal and fully enclosed print volume for handling the more temperature temperament filaments such as ABS.

The unboxing experience:

Unboxing the Creality 200B is mostly straightforward as the printer comes in one piece, no assembly required except for clicking in the rear spool holder. 2 large pieces of foam secure the printer from top and bottom and all the other contents are stored inside the build chamber, also nestled in thick protective foam while the printer is wrapped in multiple layers of plastic. The build platform is wrapped in a few layers of cling wrap which proved difficult to remove so take care with this. Lastly, the hotend assembly is held in place with a zip-tie so be sure to remove that before proceeding.

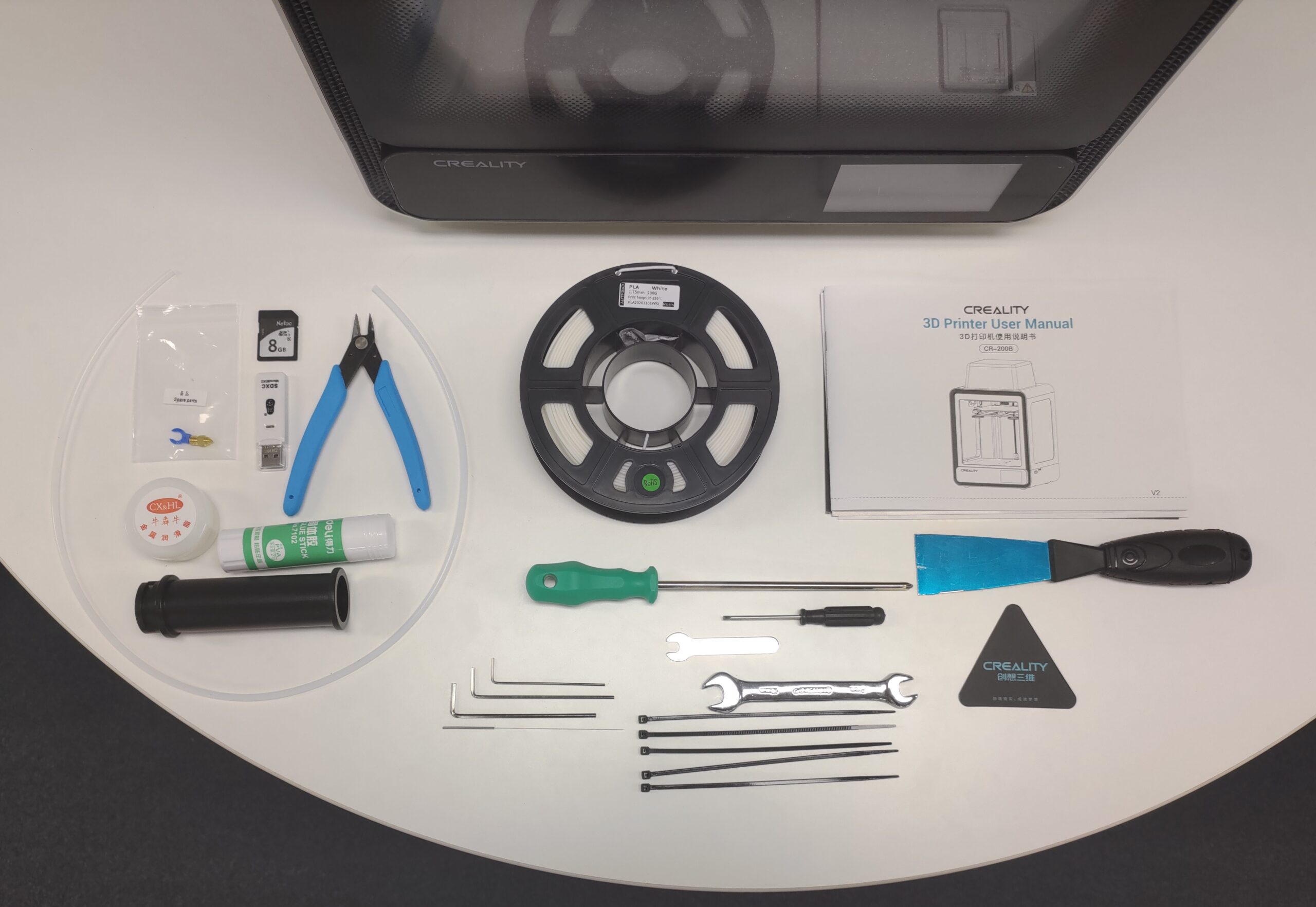

The contents:

The printer comes with your typical Creality kit conveniently packaged in an assortment of zip-lock bags. The box contains:

-

a pair of flush cutters

-

a spare nozzle and bowden coupler

-

a glue stick to keep prints stuck down

-

some grease to keep things sliding smoothly

-

a full-size SD card and sd to USB converter

-

a spare length of PTFE tube

-

some zip-ties

- 3 assorted hex keys

- a Philips head screwdriver

- a smaller flat head screwdriver

- 2 wrenches

- a scraper

- the spool holder

- the instructions and warranty.

The SD card contains some presliced gcode files for getting started with names so obscure picking one will be a guessing game, some instructions, video guides and demonstrations, firmware and a Creality slicer installer all provided in both English and Mandarin.

Included also is 200g of white Creality PLA to get you started.

The setup:

The printer coming fully assembled means setup was quite quick though the initial homing was met with a clicking noise and no movement. As mentioned earlier there was an almost hidden zip tie holding down the hotend assembly which could be quickly snipped off to continue setup just always remember to check for any restraints from the packaging before starting to use your machine, after that was sorted the machine homed quickly to 0,0. One thing noticed is the nozzle was almost 10mm above the bed even with the springs maxed out. This is solved by adjusting a small screw behind the left linear bed guide further away from the z end stop to allow the bed to go higher.

Make sure the bed isn’t heated at this point as the screw is hand turned and is quite a tight fit so your hand will be rested against the bed to reach it.

The actual levelling processes is handled with a 5 point manual levelling interface which proved to be very effective for the smaller build area.

Filament loading is a breeze with the new filament sensor design not catching on the filament like Creality’s older ones and the extruder being spaced allowing room for adjustment between the sensor and the extruder.

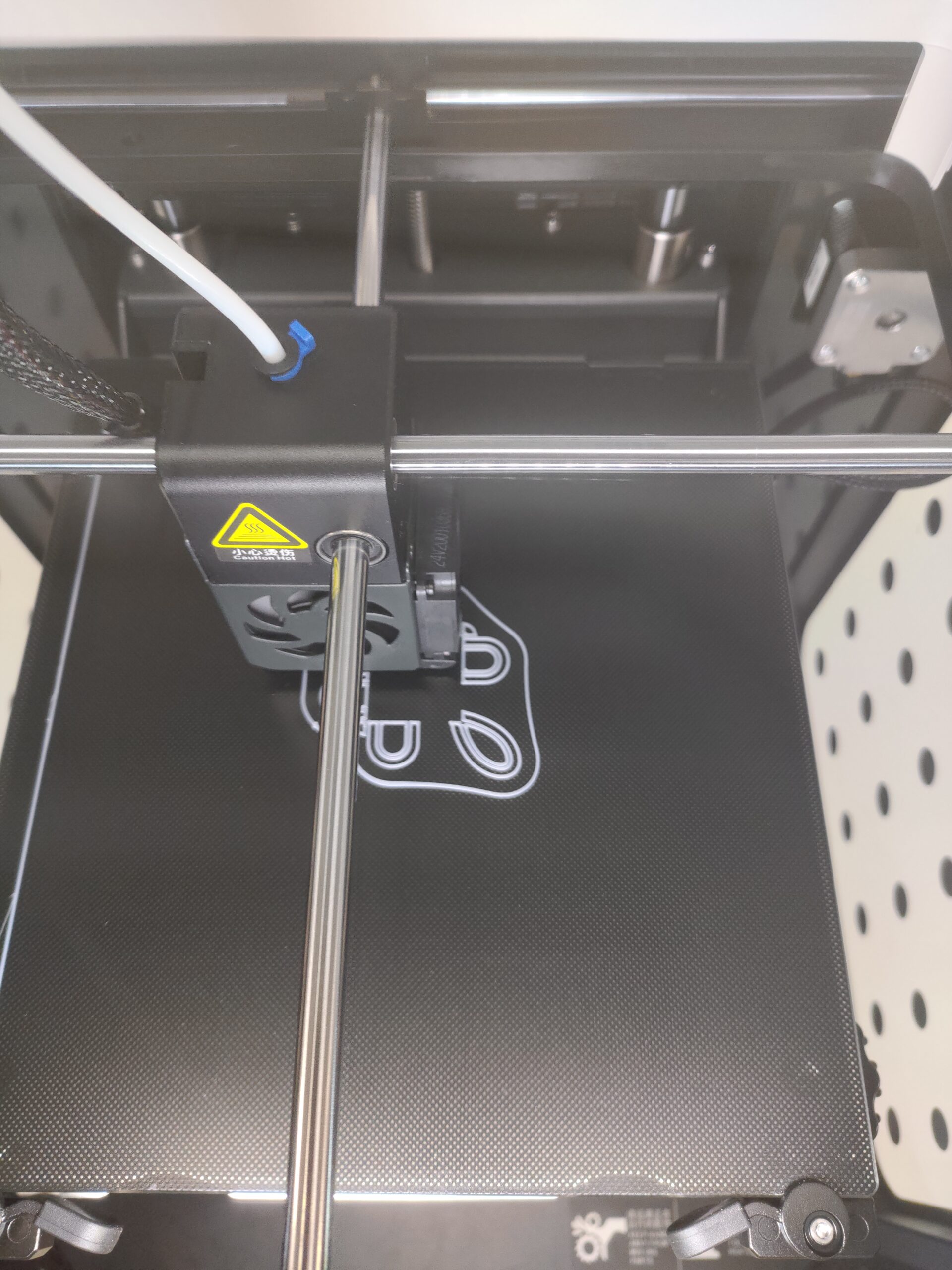

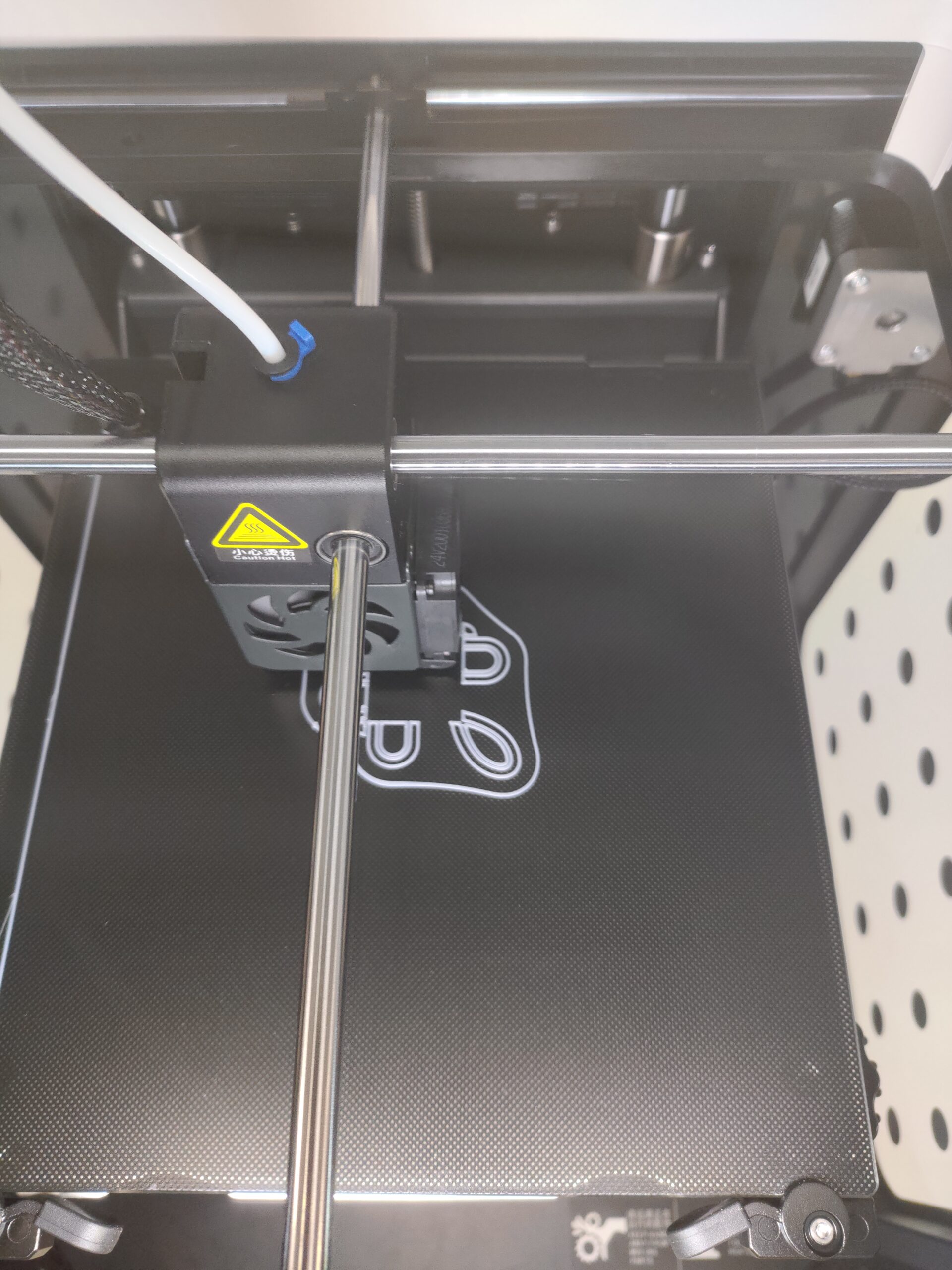

After the very fast heating, the first file on the SD card was selected and printed in about an hour and a half. While the model doesn’t seem to resemble anything recognisable it printed very well with consistent extrusion and smooth even surfaces.

The bed can also be easily removed with 2 swing out clips to release it and this is very useful as trying to stick a scraper into the enclosure to hack the print off the bed would be quite difficult though smaller prints would pop off anyway when the bed cools down.

The machine:

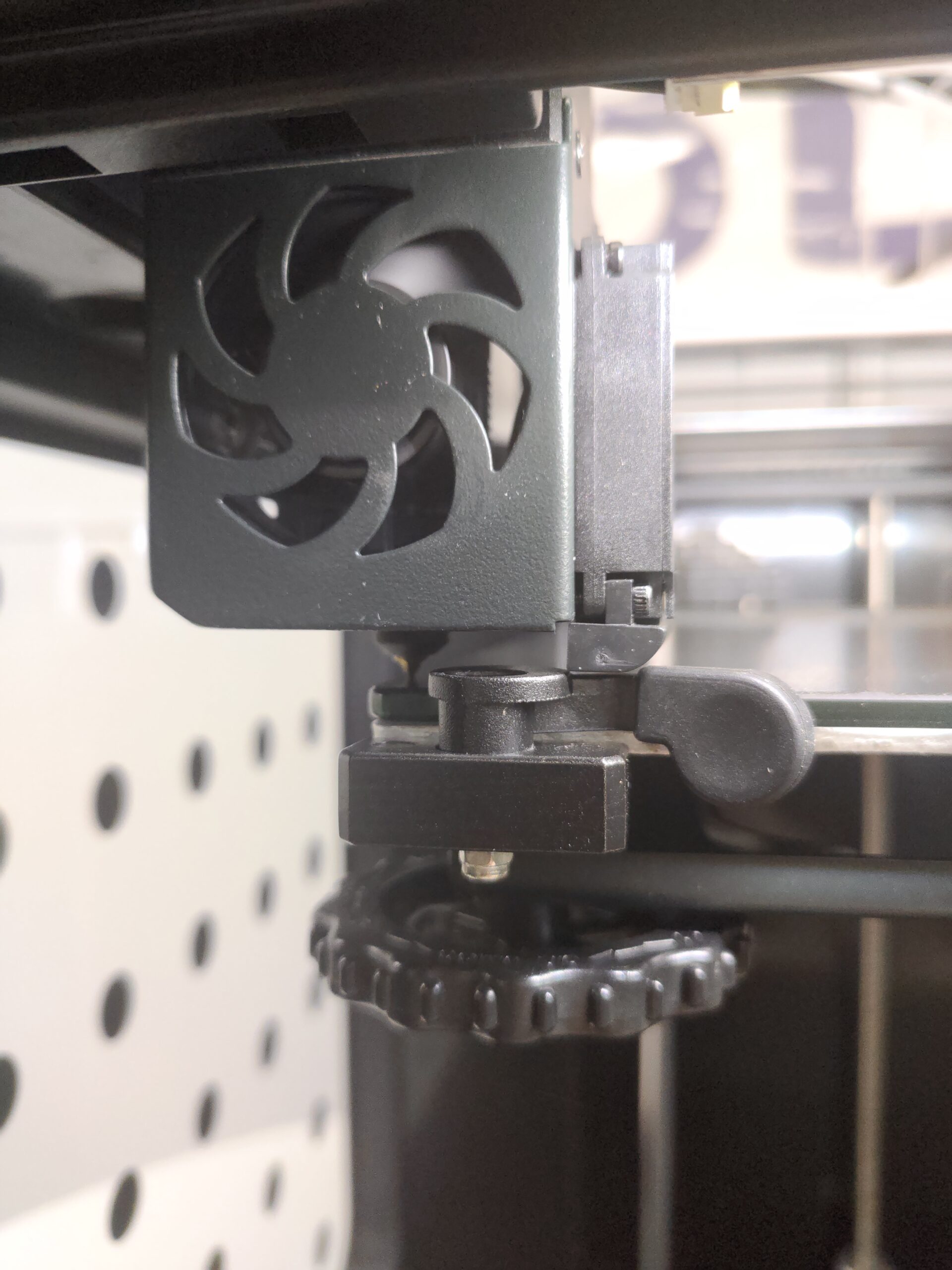

The 200B is a well-built machine with many hardware upgrades and improved parts from Creality. With a fully enclosed build volume, it will handle ABS with no issue. With integrated case cooling, it will also handle filaments like PLA, which require high cooling without leaving the door open like some other fully enclosed machines. The hotend is not all metal limiting you to <250ºc before the PTFE tube starts breaking down, but with the enclosed chamber and possibility for future upgrades, you are still open to a wide range of filament options.

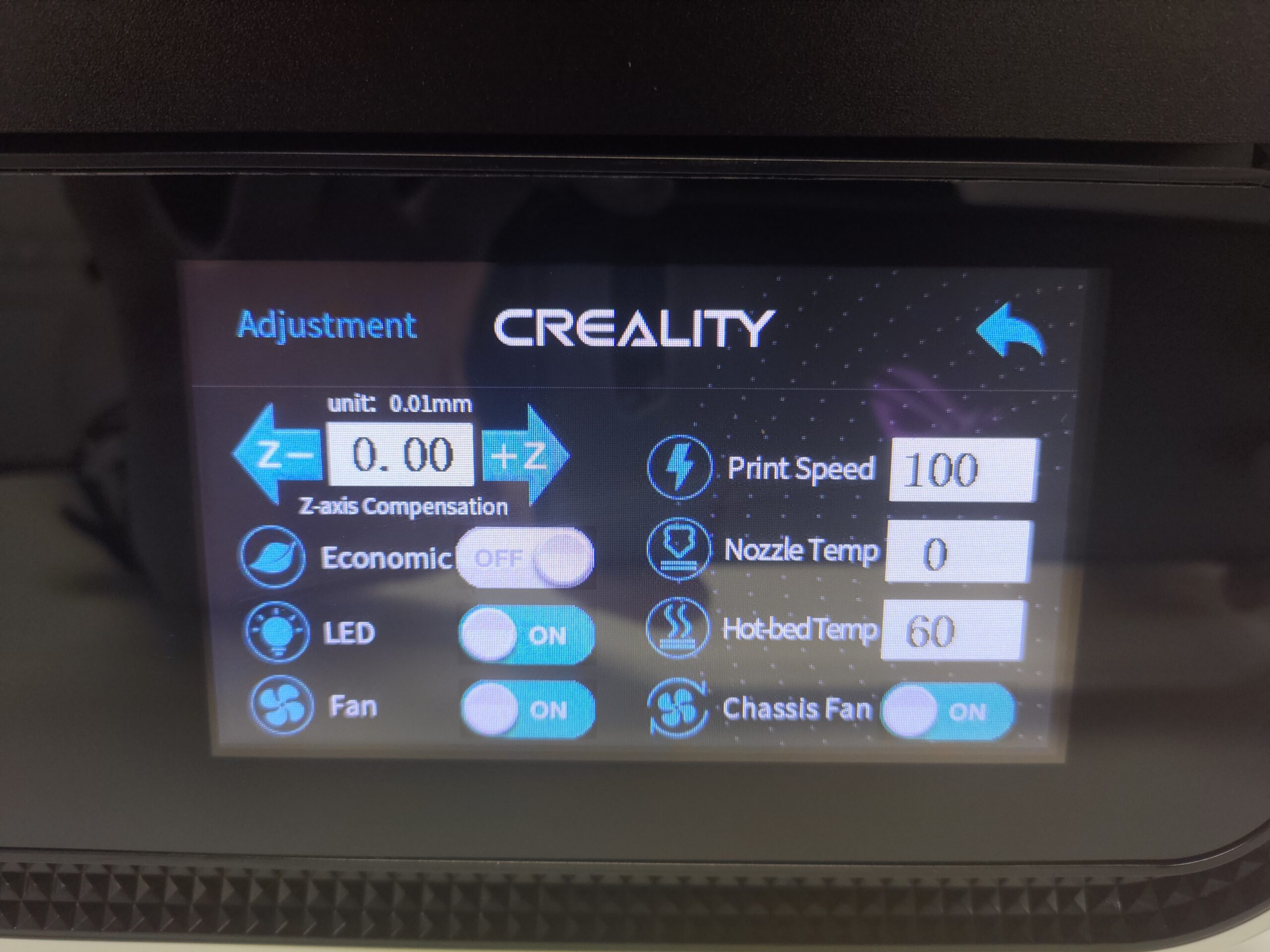

The extrusion system is bowden based, but the tube isn’t overly long and is well secured so that it won’t slip. The 200mm³ build volume is quite generous considering the printer’s footprint and will give ample room for smaller functional parts and models. The LCD touchscreen is large, incredibly responsive and hosts an updated UI with new sound design. While similar to other Creality machines, the UI is unique to this one due to extra options such as Chamber LEDs and cooling and includes all the standard options.

The hotend assembly smoothly glides on linear rods driven by completely silent steppers. However, this machine isn’t the quietest due to a large number of powerful fans to keep up with internal temperatures, but most of this noise is blocked when the chamber is closed and when printing with ABS, as you would be mostly with this machine, most of the fans aren’t active.

Lastly, this machine looks stunning. With a balanced mix of smooth-contoured plastic and tempered glass panels, interesting accents, and a minimalist colour scheme, this printer is almost a showpieceand won’t look out of place in most professional spaces such as schools and offices.

The Verdict:

In conclusion, this is a well balanced machine with hardware that is certainly up to spec and with a good profile setup you will have a very capable machine to rival its more expensive competitors that will be sure to serve you well while being very robustly build and looking the part as well.