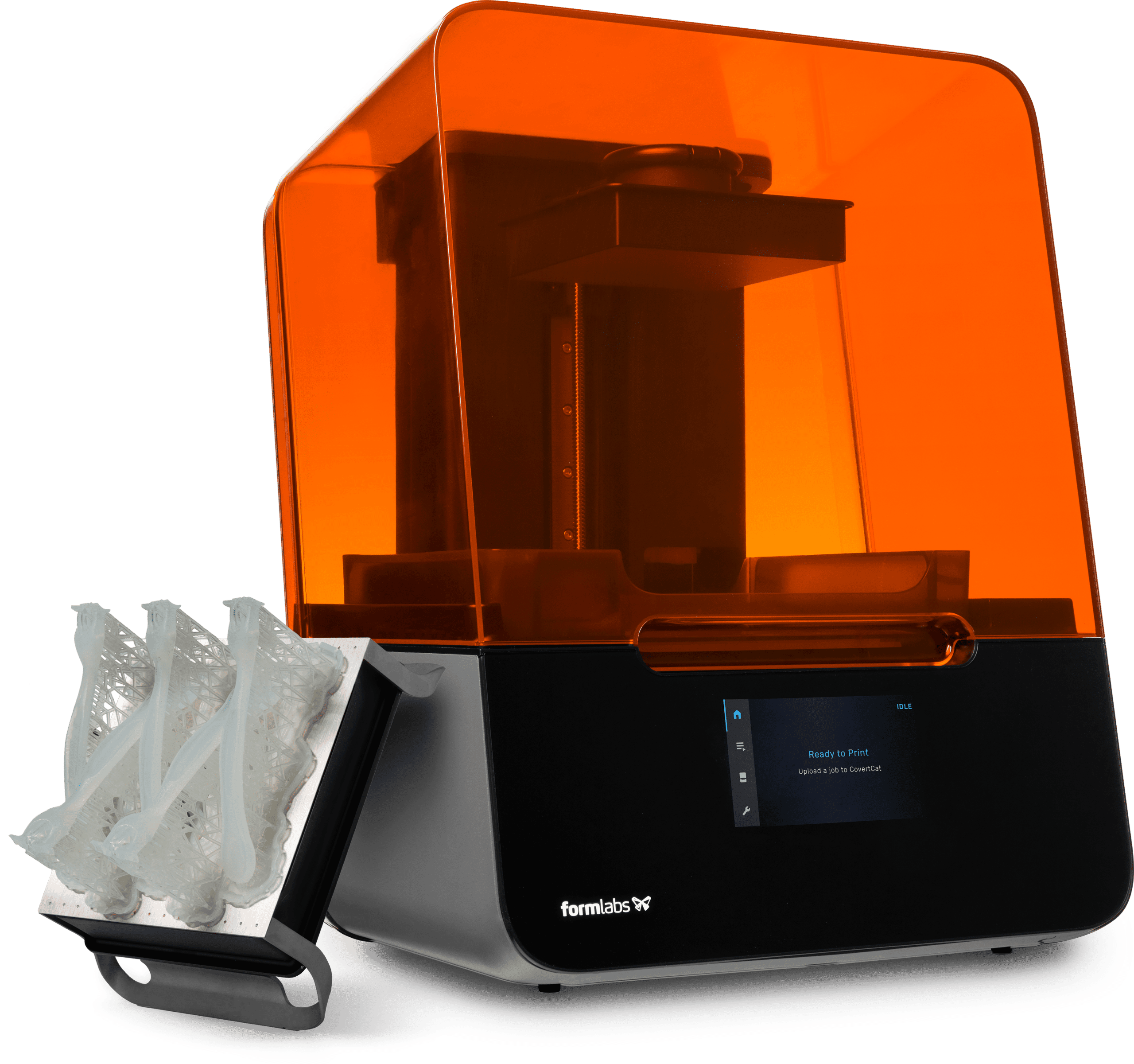

Formlabs Form 3+

Produce functional, high-quality prototypes and end-use parts in record time with Form 3+, an affordable, industrial-quality resin 3D printer that reliably delivers.

Package Options

Printer Only: Form 3+ Printer (NO RESIN TANK, BUILD PLATFORM OR FINISH KIT)

Basic Package: Form 3+ Printer, Resin Tank, Build Platform, and Finish Kit.

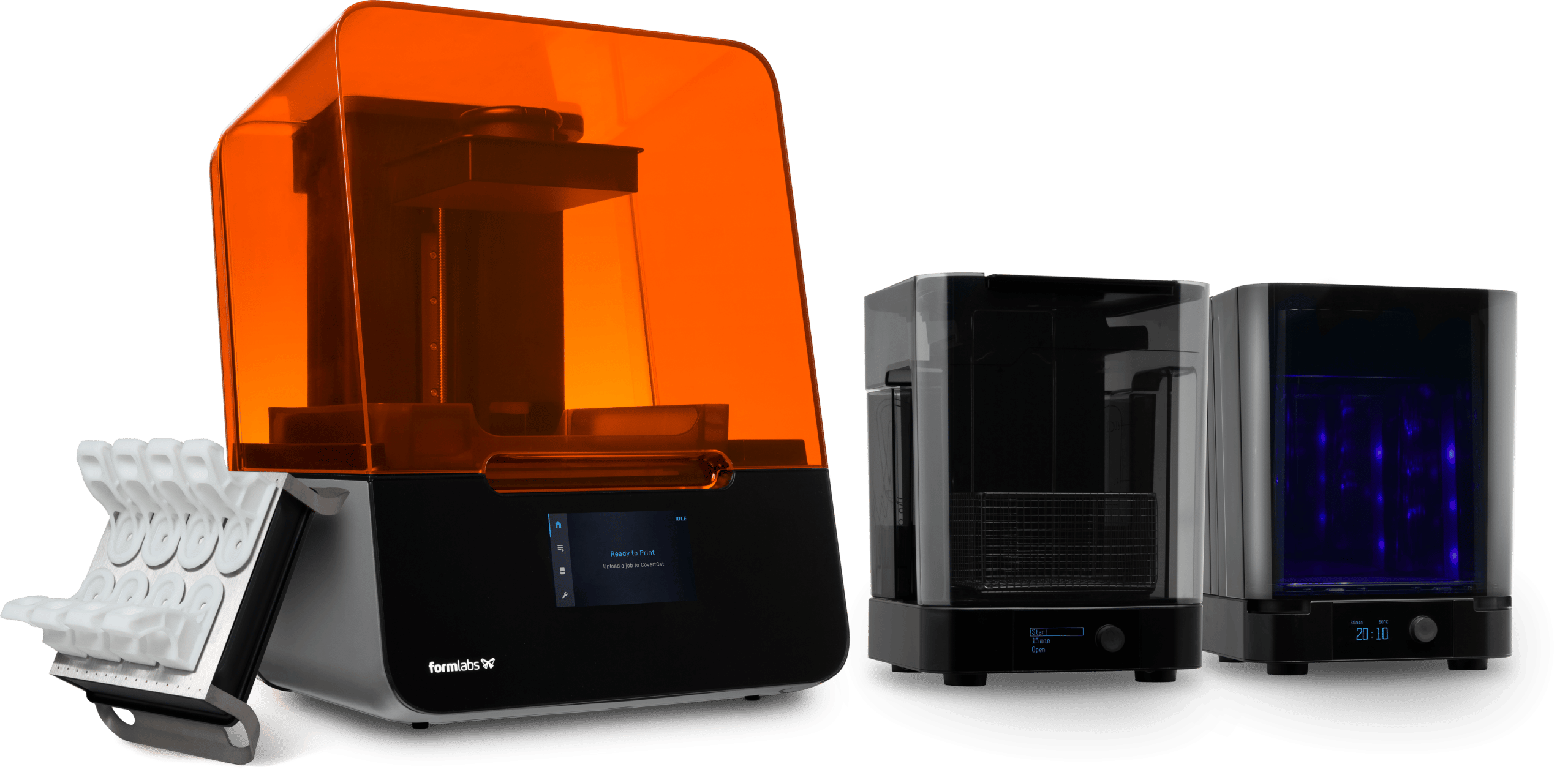

Complete Package: Form 3+ Printer, Form Wash, Form Cure, Resin Tank, Build Platform, and Finish Kits.

Special order item please allow 3-5 Business days for Tracking to be provided.

Formlabs Form 3+

Formlabs is establishing the industry benchmark for professional 3D printing for businesses around the globe with accessible, reliable 3D printers for the desktop and the benchtop. The From 3+ refines Formlabs patented LFS technology to consistently deliver presentation-ready parts with unbelievable surface finish and a vast material library.

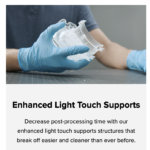

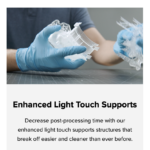

Typically the SLA printing process exerts significant forces on the part during printing introducing material limitations and requiring sturdy support structures to print successfully. Low Force Stereolithography (LFS) is a new re-engineered SLA 3D printing process which uses a flexible tank and linear illumination to deliver incredible surface quality and print accuracy with lower print forces that allow for light-touch support structures that tear away with ease and enable printing with more advanced and specialized materials.

From the beginning of your workflow to the end, the Form 3+ is the fastest, most reliable way to produce high quality prototypes and end use parts. With a suite of improvements designed to start a print easier, build a part faster, and process a part in minutes now you can scale prototyping and production as your business grows with the Form 3+, an affordable, industrial-quality 3D printer.

FORMLABS FORM 3+ FEATURES

Delivering pinpoint precision, rapid print speeds & high resolution!

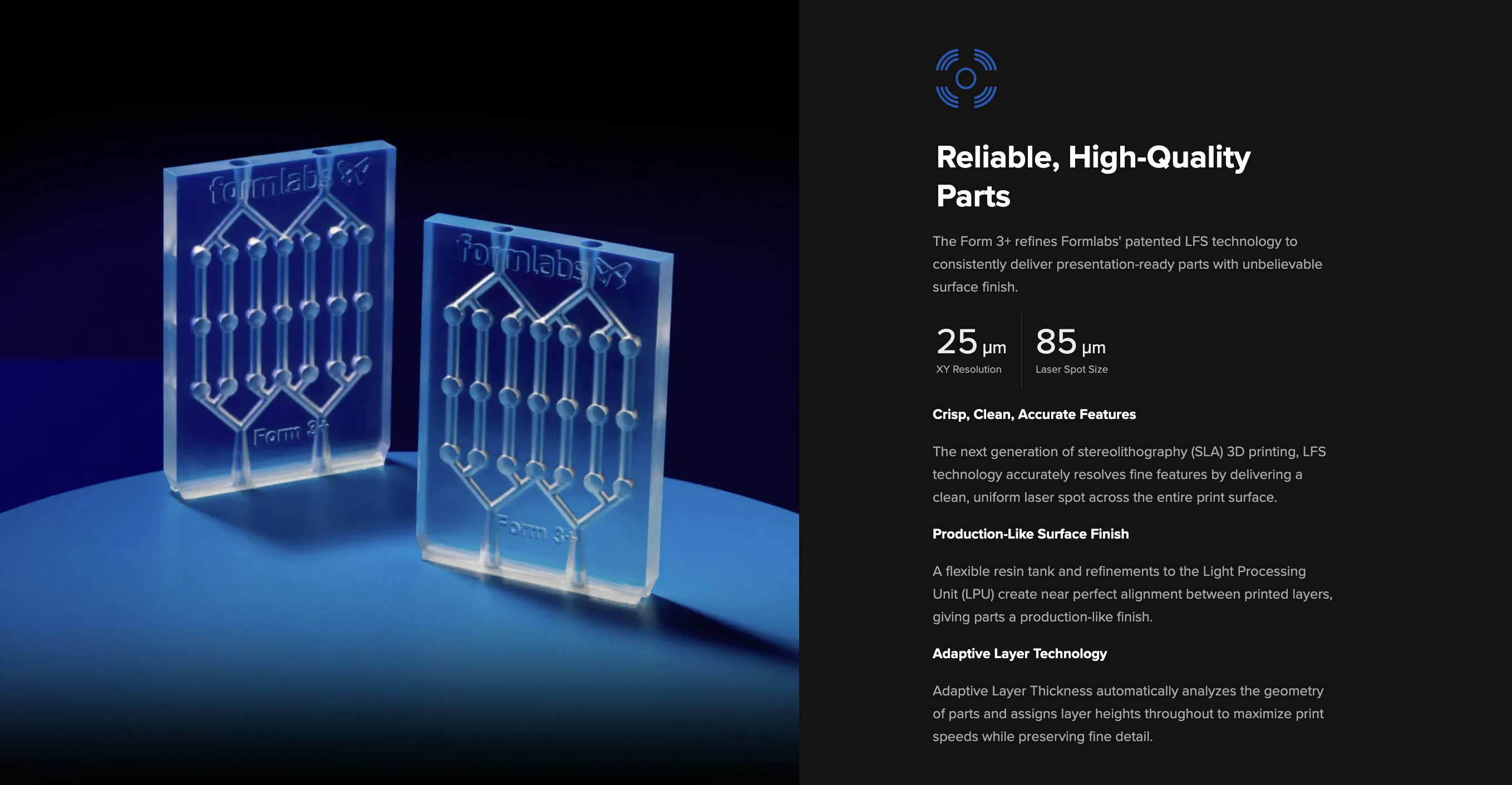

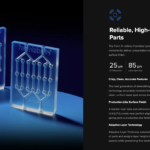

Pinpoint precision

The custom designed Light Processing Unit (LPU) maintains a uniform, high density laser spot to ensure accurate, repeatable prints. The high-power-density laser (250mW) is passed through a spatial filter to guarantee a clean laser spot to produce parts with crisp and clean features. XY laser resolution of 25μm.

Rapid print speeds

A powerful, high-intensity laser and precisely tuned settings for every material deliver rapid print speeds. Utilize Formlabs adaptive Layer Thickness to automatically analyze the geometry of parts and assigns layer heights throughout to maximize print speeds while preserving fine detail.

Smooth surface finish and high resolution

The From 3+ refines Formlabs patented LFS technology to consistently deliver presentation-ready parts with unbelievable surface finish. To achieve incredible detail and surface finish: a flexible resin tank and refinements to the Light Processing Unit (LPU) dramatically reduce forces on parts and create near perfect alignment between printed layers, giving parts a production-like finish. A parabolic mirror ensures that the laser prints perpendicular to the build plane, ensuring uniform print quality across the entire build platform. LFS technology's improved layer registration and

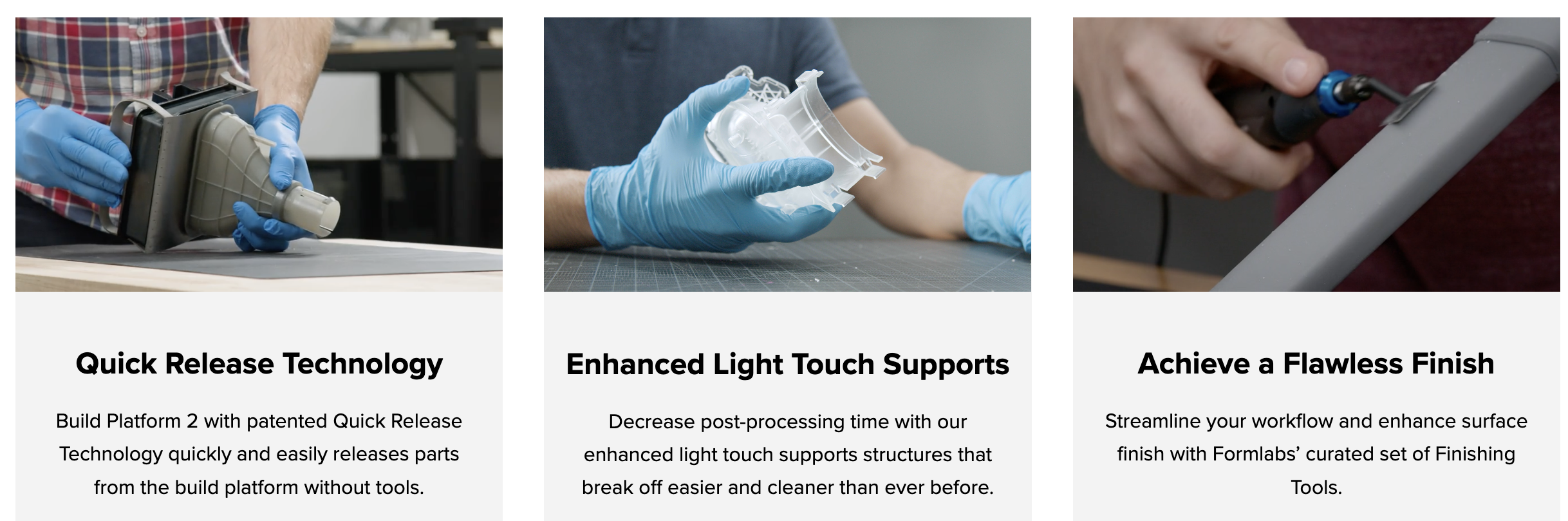

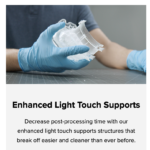

Reduce post-processing time & optimize your workflow

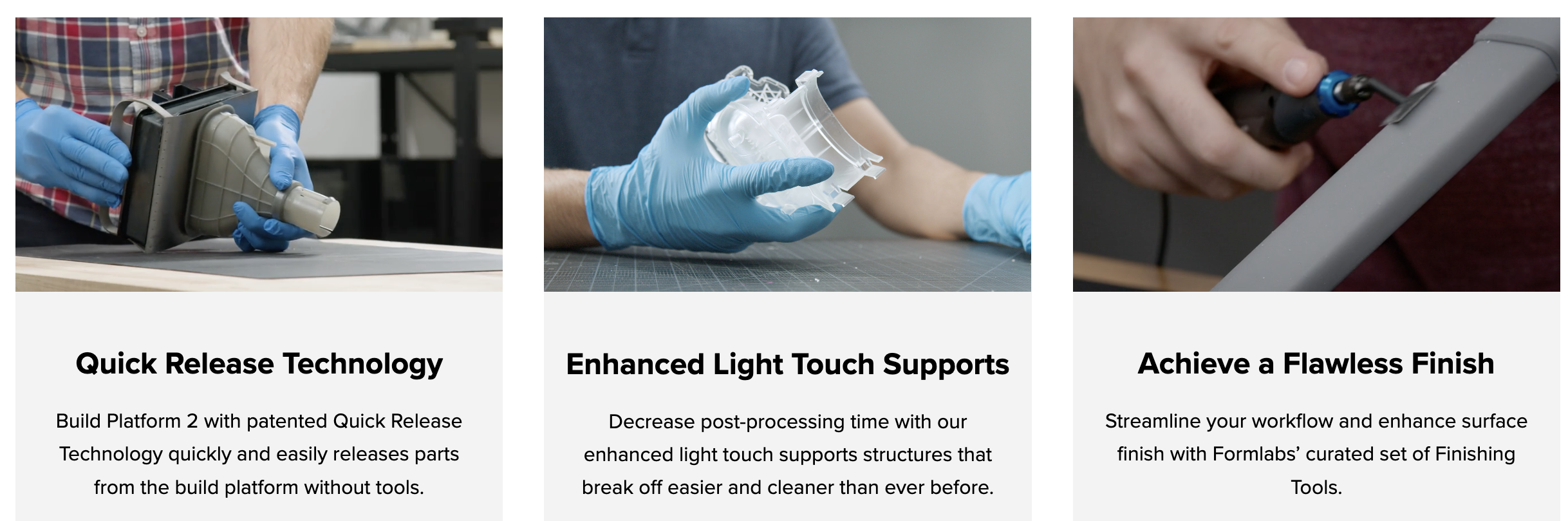

Easy Clean-up

Formlabs patented LFS technology reduces printing forces which enables printing of supports with smaller touch point size. Enhanced light touch support structures detach from parts in seconds to save post-processing time. Print smoother parts with tear-away light-touch supports on the Formlabs Form 3+.

The Perfect Finish

Complete Formlabs end-to-end solution with the Form Cure & Form Wash (sold separately). Form Wash and Form Cure streamline and automate rinsing and post-curing of prints. Consistently produce high-quality results with less time and effort.

Print the right material for your application with hassle free material management!

Easy Material Management

Print from Formlabs diverse material library with hassle free material management. Switch between materials in seconds with a simple cartridge system. With simplified material switching and automatic resin dispensing, the Form 3+ allows you to walk away and focus on other work once your print job starts.

Formlabs Material Library

Form 3+'s material compatibility enables one Form 3+ 3D printer to be used for a wide range of different applications whether it be producing architecture models, jigs and fixtures, low friction assemblies, stretchable enclosures, short-run injection mold masters or heat resistant and fluid exposed components. Explore Formlabs resins.

Designed to effortlessly integrate into your office or factory

Nonstop printing

The Form 3+ constantly monitors print performance so you can focus on bringing your most creative ideas to life. Integrated sensors help maintain ideal print conditions and send you alerts about the state of your machine.

Closed-loop calibration

Optical sensors continuously correct for scale and power, and can even detect dust.

Remote Print

3D print from anywhere via the online Dashboard.

SCALE PRODUCTION WITH THE FORM 3L ECOSYSTEM

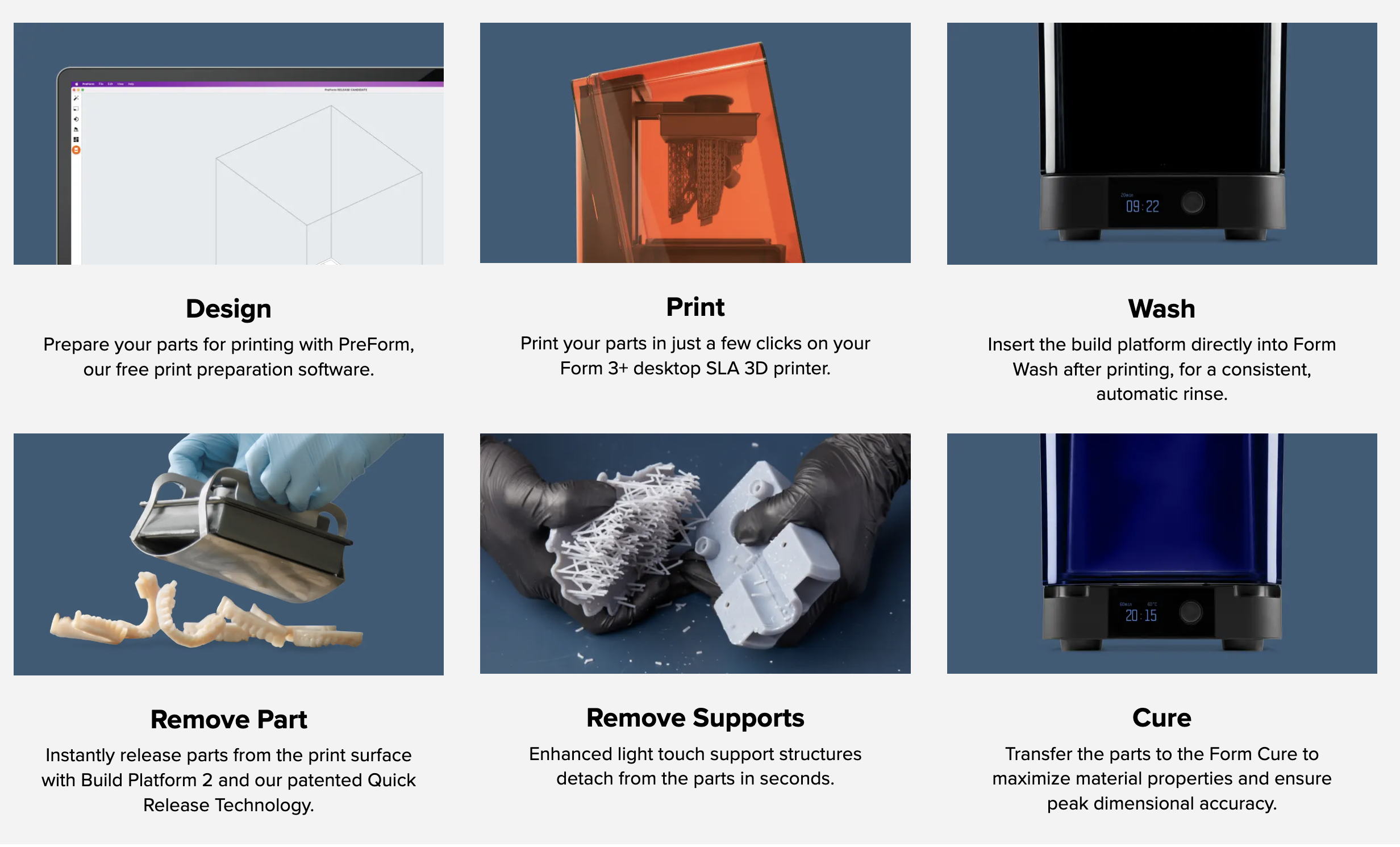

Optimize your workflow with the complete Form 3 ecosystem. From setting up your print to post-processing your part, Formlabs suite of Form 3 products streamlines the 3D printing workflow from printing to post-processing.

Wash and cure your models and prototypes with the Form Wash (sold separately) and maximize material properties with the Form Cure (sold separately). The Form Wash and Form Cure are included in the Formlabs Form 3+ Complete Package

PRINTING PROPERTIES

| Printing Technology | Low Force Stereolithography (LFS)™ |

|---|---|

| Resin Fill System | Automated |

| Build Volume (W x D x H) |

14.5 × 14.5 × 18.5 cm |

| Layer Thickness (Axis Resolution) ᵇ | 25 – 300 microns |

| XY Resolution ᵃ | 25 microns |

| Laser Spot Size | 85 microns |

| Resin Cartridges | 1 |

| Biocompatible Materials | No (available on Form 3B+) |

| Supports | Auto-Generated Light-Touch Removal |

ᵃ XY resolution describes how precisely the printer can draw in the XY (horizontal) plane.

ᵇ Layer thickness availability varies by material. View our materials compatibility table to confirm availability.

HARDWARE

| Minimum Access Dimensions (W × D × H) | 40.5 × 53 × 78 cm |

|---|---|

| Printer Dimensions (W × D × H) | 40.5 × 37.5 × 53 cm |

| Weight | 17.5 kg |

| Internal Temperature | Auto-heats to 35 °C |

| Temperature Control | Air-heated print chamber |

| Operating Environment | 18 – 28 °C |

| Power Requirements | 100–240 VAC, 2.5 A 50/60 Hz, 220 W |

| Laser Specifications | 1 Light Processing Unit EN 60825-1:2007 certified Class 1 Laser Product 405 nm wavelength 250 mW power 85 micron (0.0033 in) laser spot |

| Connectivity | Wi-Fi (2.4, 5 GHz) Ethernet (1000 Mbit) USB 2.0 |

| Printer Control | 5.5″ interactive touchscreen 1280 × 720 resolution |

| Alerts | Touchscreen alerts SMS/email via Dashboard Two LED status indicators Speaker for audio alerts |

SOFTWARE

| System Requirements | Windows 7 (64-bit) and up Mac OS X 10.12 and up OpenGL 2.1 4 GB RAM (8 GB recommended) |

|---|---|

| Hardware Requirements | Form 3+, Form3, Form 3L, Form 3B+, Form 3B, Form 3BL, or Form 2 3D printer |

| File Types | STL and OBJ file input FORM file output |

| PreForm Print Setup Features | One-Click Print Adaptive layer thickness for faster printing with fine details Remote Print Auto-orient for optimal print position Auto-mesh repair Auto-generation of supports Rotate, scale, duplicate, and mirror Layer slicer for path inspection Available in multiple languages |

| Dashboard Printer Management Features | Manage prints and printers via the cloud Track resin and tank usage over time SMS and email alerts Create enterprise group accounts with admins to more easily share printers and control access |

There are no reviews yet.