In the world of 3D printing, accessories play a critical role that goes far beyond mere augmentation of the printing process. These tools and add-ons are pivotal in transforming a basic printing setup into a high-functioning, efficient, and versatile printing station. They do more than just support the process; they enhance every aspect of it.

Improving Print Quality

One of the most significant roles of these accessories is the enhancement of print quality. For instance, specialised nozzles can provide finer detail or allow for the use of more abrasive materials, thereby expanding the range of possible print projects.

Similarly, upgraded print beds lead to better adhesion and smoother first layers, which are fundamental for the success of the entire print. Tools like cooling fans and modulators play a subtle yet powerful role in ensuring that each layer is set perfectly before the next is applied, crucial in intricate designs where every millimetre matters.

Ensuring Longevity of the Printer

Beyond improving the immediate outcome of a print, these accessories are vital in maintaining the printer’s health over time. Regular use can take a toll on the machine, but with the right maintenance tools – like cleaning kits, lubricants, and replacement parts – the lifespan of a printer can be significantly extended. This not only optimises the value of the investment but also ensures consistent print quality over time.

Expanding Capabilities

3D printer accessories also open up new possibilities. With the addition of certain tools, a basic 3D printer can be transformed to handle a wider range of materials, experiment with different printing techniques, or even perform multiple functions like engraving or cutting. This adaptability is particularly valuable in rapidly evolving fields, where the ability to pivot and embrace new technologies can be a game-changer.

Enhancing User Experience

The convenience and ease of use provided by these accessories cannot be overstated. Whether it’s a filament holder that ensures smooth feed into the printer or a software upgrade that simplifies the design-to-print process, these enhancements make 3D printing more accessible and enjoyable.

For hobbyists and professionals alike, the user experience is a key factor in the overall satisfaction with 3D printing, and accessories play a substantial role in optimising this aspect.

Safety & Environmental Considerations

In addition to functionality, some 3D printer accessories are designed with safety and environmental sustainability in mind. Enclosures, for instance, not only help in maintaining consistent temperature but also contain any potentially harmful fumes. Filament recyclers and eco-friendly options contribute to a more sustainable practice, aligning with the growing global emphasis on environmental consciousness.

Essential 3D Printing Tools

The 3D printing world is a universe of its own, teeming with specialised tools that cater to various aspects of the printing process. These tools are not just conveniences; they are necessities for anyone serious about 3D printing.

Understanding the types of tools available and their specific purposes is the first step in optimising your 3D printing workflow. Whether it’s tools for post-processing or maintenance, each plays a unique role in enhancing the overall printing experience.

Spatulas & Removal Tools

One of the first hurdles you encounter in 3D printing is safely removing your finished print from the bed. This step is more nuanced than it appears, as improper removal can damage both the print and the printer’s bed. A good spatula or removal tool is designed to neatly slide under the print, offering enough leverage to lift it without exerting undue stress on either the print or the bed.

Some spatulas come with a very thin edge to slide easily under prints, while others are more rigid for sturdier objects. Choosing the right tool for your specific printer and print type can save a lot of hassle and prevent potential damage.

Precision Pliers & Tweezers

When you venture into more complex prints, particularly those with intricate details or multiple supports, precision tools like pliers and tweezers become indispensable. These tools allow for the careful removal of supports and excess material, ensuring the final print retains its intended shape and detail.

Precision pliers can grip and snip small, hard-to-reach sections of support material, while tweezers are perfect for removing small strings or blobs of plastic that often form during printing. For those striving for perfection in their prints, these tools are invaluable for the kind of detailed post-processing that elevates a good print to a great one.

Cleaning Kits

The maintenance of a 3D printer is as important as any stage of the printing process. Over time, printers can accumulate debris and filament residue, which can affect print quality and lead to mechanical issues. A comprehensive cleaning kit typically includes various brushes, lubricants, and cleaning solutions designed specifically for 3D printers.

Regular use of these tools can keep your printer running smoothly and ensure consistent print quality. Some kits even include tools specifically designed for cleaning the printer’s nozzle – a common site for clogs and blockages. Proper maintenance not only extends the lifespan of your printer but also maintains the quality of your prints.

Filament Management

Effective filament management is a cornerstone of successful 3D printing. The quality of the filament directly impacts the quality of the print. Therefore, proper storage and handling of your filaments is essential.

Filament Storage Solutions

The way you store your filament can have a profound effect on its usability and longevity. Filaments are prone to absorbing moisture from the air, which can lead to issues like brittleness, bubbling, and poor adhesion during printing.

Additionally, dust and other environmental contaminants can adhere to the filament, potentially clogging the printer’s extruder and nozzle. Therefore, proper storage solutions are not just a convenience but a necessity.

Dry Boxes

Dry boxes are a popular and effective solution for filament storage. These sealed containers protect the filament from environmental factors, particularly moisture. Moisture absorption is a critical concern, especially in areas with high humidity. When the filament absorbs moisture, it can lead to a myriad of printing problems, including uneven extrusion and poor surface finish.

Dry boxes often come equipped with desiccants, like silica gel, to actively absorb any moisture in the air inside the box. Some advanced models even maintain a controlled environment with humidity sensors and dehumidifiers, ensuring the filament remains dry and in optimal condition for printing.

Filament Spool Holders

Filament spool holders play a crucial role in ensuring a smooth and consistent feed of filament into the printer. A good spool holder reduces the resistance and tangling of the filament as it unwinds from the spool. This smooth unwinding is essential for consistent print quality, as it prevents issues like under-extrusion or filament breakage.

Furthermore, well-designed spool holders can accommodate different sizes and shapes of spools, making them versatile for various types of filament. Some spool holders also offer features like filament guides and tension control, which further enhance the stability and consistency of the filament feed.

Print Bed Upgrades

The print bed is one of the most crucial elements in a 3D printer setup. It’s not just a platform where your objects materialise; it plays a significant role in determining the quality and success of your prints. Upgrading your print bed can lead to substantial improvements in print adhesion, which is vital for accurate and reliable printing.

Types of Print Beds

Upgrading the print bed of your 3D printer can bring about transformative changes in your printing process. Different materials used for print beds offer unique advantages, catering to various printing needs and preferences.

Glass Beds

Glass beds are renowned for providing a smooth, flat surface, which is crucial for the first layer of your print. A smooth first layer is essential for the overall aesthetics and structural integrity of the print. Glass beds are also relatively easy to clean and maintain.

They are ideal for prints that require a glossy bottom finish. However, it’s important to note that glass beds can take longer to heat up and might require additional adhesion promoters like glue or hairspray.

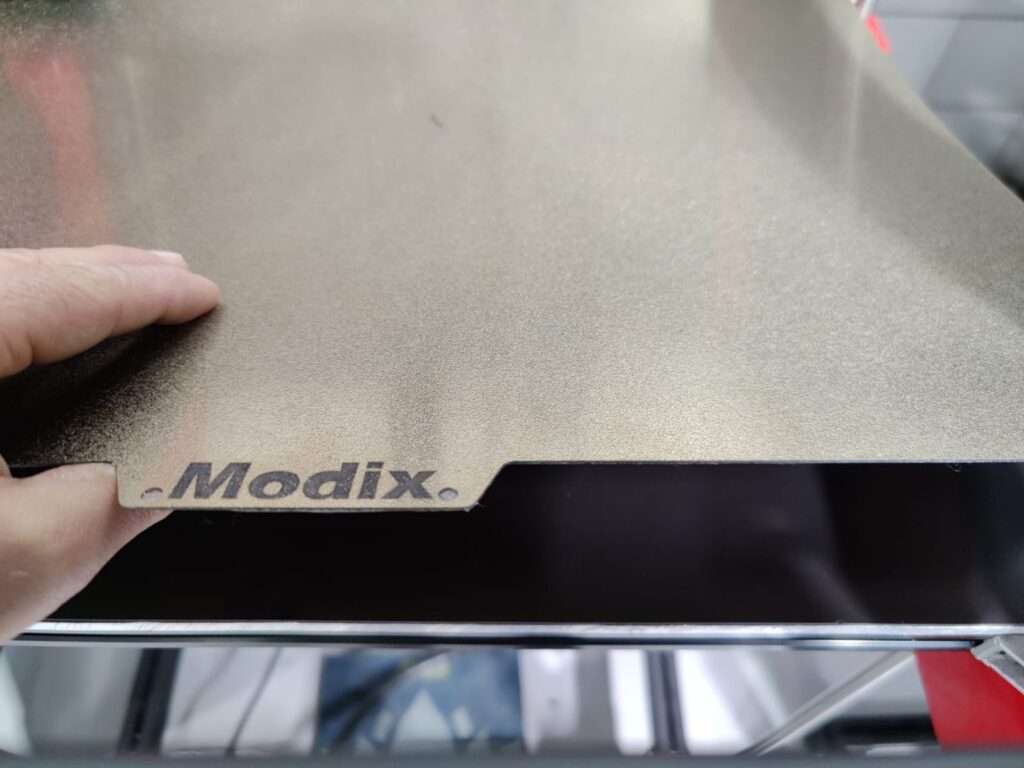

Magnetic Beds

Magnetic beds offer convenience and ease of use, particularly when removing finished prints. The magnetic surface allows for the flexible removal of the print bed, enabling you to easily detach and flex it, popping the print off without the need for scrapers or other tools. This feature is especially beneficial for delicate prints where mechanical removal could cause damage.

PEI (Polyetherimide) Beds

PEI beds have gained popularity for their excellent adhesion properties. A PEI surface, often applied as a thin sheet on top of another bed type, provides strong adhesion when hot and releases easily when cooled. This self-releasing feature minimises the need for additional adhesives and makes the print removal process much smoother. PEI beds are great for a wide range of filament types, offering versatility and consistent performance.

Importance of Bed Levelling

Regardless of the type of bed you choose, levelling remains a critical factor in achieving successful prints. An uneven bed can lead to a multitude of issues such as poor adhesion, layer misalignment, and even complete print failure.

Tools & Techniques for Levelling

Ensuring a perfectly levelled bed is paramount, and there are various tools and techniques to achieve this. Manual levelling involves adjusting the bed’s height at several points using knobs or screws, often guided by a piece of paper to gauge the distance between the bed and the nozzle.

For a more automated approach, there are sensors and add-ons that can automatically measure and adjust the bed’s level. These automated systems can significantly simplify the levelling process, making it more accessible to beginners and ensuring greater accuracy for advanced users.

Calibration & Measurement Tools

In the realm of 3D printing, precision is not just a preference; it’s a necessity. The accuracy with which a printer can replicate a design determines the quality and fidelity of the print.

Even the slightest deviation, as minuscule as a fraction of a millimetre, can result in flaws that range from cosmetic imperfections to complete structural failures. This is where calibration and measurement tools come into play, serving as the guardians of accuracy in the 3D printing process.

Importance of Precision

The pursuit of precision in 3D printing is akin to a fine balancing act. Every component of the printer, from the extruder to the print bed, needs to operate with exactitude. This is especially crucial when creating complex, multi-part assemblies or detailed models where each piece must fit perfectly with the others. Inaccuracies not only affect the aesthetics but can also impact the functional aspects of printed objects, such as gears, hinges, or interlocking parts.

Callipers & Micrometers

Digital callipers, in particular, are a favourite among 3D printing enthusiasts for their ease of use and precise readings. They are used to measure the dimensions of printed objects, ensuring they match the intended design. Callipers can also be used to check the filament diameter, which is critical for accurate extrusion settings.

Micrometers provide an even higher level of precision, typically used when ultra-accurate measurements are necessary. They are ideal for verifying the smallest details in a print or the printer components themselves.

Automated Bed Levelling

For those seeking a more streamlined and hassle-free experience, automated bed levelling sensors are a game-changer. These advanced devices take the guesswork out of the levelling process. They work by probing various points on the bed and automatically adjusting the print head to compensate for any unevenness.

This not only saves time but also enhances the reliability and consistency of prints. It’s a particularly beneficial upgrade for beginners who might find manual levelling challenging and for professionals who value efficiency and precision.

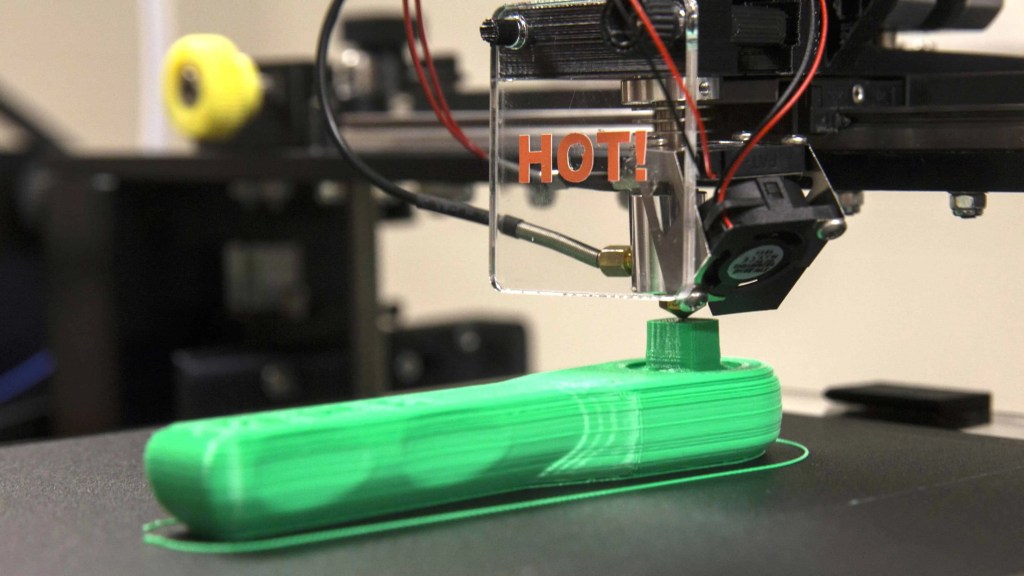

Enhanced Cooling & Temperature Control

Effective temperature management is a critical factor in achieving high-quality 3D prints. The way a printer manages heat can significantly impact the final result, affecting everything from the print’s structural integrity to its aesthetic appearance.

This is particularly true for prints with complex geometries, such as overhangs and bridges. Enhanced cooling systems and temperature monitoring tools are therefore essential in ensuring optimal printing conditions.

Cooling Fans

These fans are designed to rapidly cool the material as it is extruded. This rapid cooling is crucial for preventing warping and deformation, which can occur when layers of the print do not cool uniformly. It’s particularly important in prints with overhangs or bridges where the material is extruded over open air. Without effective cooling from cooling fans, these sections can droop or fail, compromising the print’s integrity.

Ducts

Ducts are equally important as they direct the airflow from the cooling fans precisely where it is needed. A well-designed duct ensures that the airflow is focused on the tip of the extruder, providing targeted cooling to each new layer as it’s deposited. This targeted approach is key to maintaining shape and detail in complex prints.

Temperature Monitoring Tools

While cooling is essential, maintaining the overall optimal temperature within the printer is also crucial. Temperature fluctuations can lead to inconsistent extrusion and poor layer adhesion.

Thermometers & Sensors

Temperature monitoring tools, such as thermometers and thermal sensors, are employed to keep a close eye on the printing environment. These tools can provide real-time feedback on the temperature inside the printer, allowing for adjustments on the fly.

Automated Temperature Control

More advanced 3D printers incorporate automated temperature control systems. These systems use sensors to constantly monitor the temperature and automatically adjust the heating elements and cooling fans to maintain a stable printing environment. This is particularly important when working with materials that have a narrow temperature window for optimal printing.

Safety & Environmental Accessories

The realm of 3D printing, while innovative and exciting, also presents various safety and environmental challenges. As 3D printers operate at high temperatures and often use materials that can emit fumes, it’s important to consider accessories that not only enhance the printing experience but also ensure safety and environmental responsibility. Enclosures, filters, and fire safety tools are crucial in this regard.

Enclosures

An enclosure is a physical barrier that surrounds the printer, creating a controlled environment. This containment helps in maintaining a consistent temperature, which is especially beneficial for materials prone to warping or splitting due to temperature fluctuations. Enclosures also significantly reduce noise, which is an added advantage in commercial settings.

Protection from Fumes

More importantly, enclosures are vital for safety, particularly when working with materials like ABS (Acrylonitrile Butadiene Styrene) that emit fumes during printing. These fumes, if inhaled, can pose health risks.

Filters

To tackle the issue of emissions, many enclosures come equipped with filters. These filters are designed to trap or neutralise harmful particles and fumes, thereby reducing exposure to any potentially toxic emissions. Active carbon filters and HEPA (High-Efficiency Particulate Air) filters are commonly used, each designed to capture different types of particles and gases.

Fire Extinguishers & Alarms

Having a fire extinguisher specifically designed for electrical fires is a prudent safety measure. Additionally, smoke detectors and thermal sensors can provide early warnings in case of any overheating or potential fire hazards. These tools are essential, especially for those who operate their printers unsupervised or overnight.

Automated Safety Features

Some advanced 3D printers come with built-in safety features, such as automatic shutdown in the event of overheating or other malfunctions. For those using printers without these features, aftermarket solutions are available that can add an extra layer of safety to the printing setup.

Advanced Modifications

Advanced modifications in 3D printing open up a world of possibilities, allowing enthusiasts and professionals alike to expand beyond the basics of single-material printing. These modifications, such as dual extrusion kits and laser engraving add-ons, enhance the capabilities of a standard 3D printer, transforming it into a multi-functional tool that caters to a broader range of creative and practical applications.

Dual Extrusion Kits

Dual extrusion kits are a significant upgrade for those looking to explore the realms of multi-material and multi-colour 3D printing.

With a dual extrusion setup, a printer can handle two different types of materials or colours at the same time. This capability is particularly useful for creating complex models with moving parts, supports in dissolvable materials, or objects with distinct colour patterns. It opens up a new dimension of creativity, allowing for the production of more sophisticated and functional designs.

Technical Considerations

Implementing a dual extrusion system does come with its challenges. It requires careful calibration and setup, as the two extruders must work in harmony without interfering with each other. This can involve precise alignment and balancing of the nozzles and a deeper understanding of the printing software to manage the dual-feed system effectively.

Laser Engraving Add-Ons

Laser engraving add-ons represent another frontier in the diversification of 3D printing capabilities. These add-ons equip a 3D printer with the ability to engrave designs onto various materials like wood, plastic, and certain metals. The precision of laser engraving allows for intricate designs and text, adding a professional touch to personal or commercial projects.

Safety & Compatibility

When integrating a laser engraving system, safety becomes paramount. It’s important to use protective eyewear and ensure that the laser is compatible with your 3D printer model. Additionally, proper ventilation is necessary to manage any fumes or particles produced during the engraving process.

Unleashing the Full Potential of 3D Printing: The Power of Accessories & Modifications

The realm of 3D printing is as vast as it is fascinating, offering endless possibilities for creativity, innovation, and practical application. The journey from a simple print to a masterpiece of precision and functionality hinges significantly on the tools and accessories that accompany the printer. From essential tools like spatulas and precision pliers to advanced modifications like dual extrusion kits and laser engraving add-ons, each component plays a pivotal role in the printing process.

Understanding and utilising these accessories can dramatically improve both the experience and the outcome of your 3D printing endeavours. Whether it’s ensuring the longevity and maintenance of your printer with proper filament storage and cleaning kits, enhancing print quality through upgraded beds and calibration tools, or expanding the capabilities of your printer with advanced modifications, each element contributes to a more efficient, safe, and enjoyable printing journey.

As the technology continues to evolve, so too do the 3D printing accessories and modifications available, each offering new ways to explore and push the boundaries of what can be achieved with 3D printing. The key to mastering this craft lies in a blend of knowledge, experimentation, and the right set of tools.

Regardless if you’re a beginner just starting out, a hobbyist looking to enhance your printing experience, or a professional seeking to optimise your workflow, the world of 3D printing accessories offers a treasure trove of opportunities to explore. Embrace these tools, and watch as your 3D printing projects transform from mere concepts into tangible, high-quality realities.